How to detect overloaded circuits and defective breakers in your house.

Oct 28 2013 · 0 comments · electrical, Home Inspection, Infrared Thermography

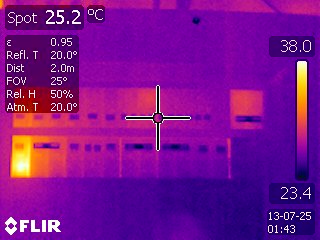

A thermogram of an electrical panel with the bottom left breaker hotter compared to the other breakers. The breaker was not a GFCI breaker. Further evaluation of the breaker and circuit is required to determine the reason.

Infrared thermal imaging is an awesome tool in electrical inspections. Best of all, it is safe for the inspector as we do not touch any electrical equipment during the inspection.

As we know, good infrared cameras are good at detecting heat differences in high precision. This means that the camera can identify and produce thermograms to show materials with very small temperature differences. This is great for detecting moisture damage around the house.

This is also a helpful and important feature when we inspection the electrical components of the house. The infrared camera is particularly good at detecting overloaded circuits and breakers. An overloaded circuit is protected by breakers that trip or fuses the blow when the current drawn is in excess of the rated breaker or fuse. What if the current is incorrectly protected with a higher amperage then what the wires are rated for? A common mistakes home owners make is using a 14 AGW with 20 A or 30A breakers. The breakers would not trip until the current drawn reached 20 A or 30 A depending on the breakers used. In the mean time, the 14 AGW copper wire is being heated as more current is being drawn then what the wire thickness can handle. The hazard here is the wire can melt the sheathing and worst, a potential electrical fire hazard.

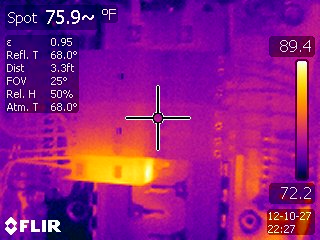

If current was being drawn during the inspection, the infrared camera would pickup the heated wire. If left on long enough, the wire behind drywall can also be detected by the infrared camera. The infrared camera can also sense breakers working close to their rated limit. If detected, the breaker should be examined closer for possible causes. Some breakers with built in GFCI are warmer compared to regular breakers, in this case, if the built-in GFCI breaker was the same temperature as other breakers, then there would be a problem with the GFCI breaker.

This thermogram may appear similar to the one on top, but they are different electrical panels. The glowing breaker here is actually normal as it is a GFCI type.